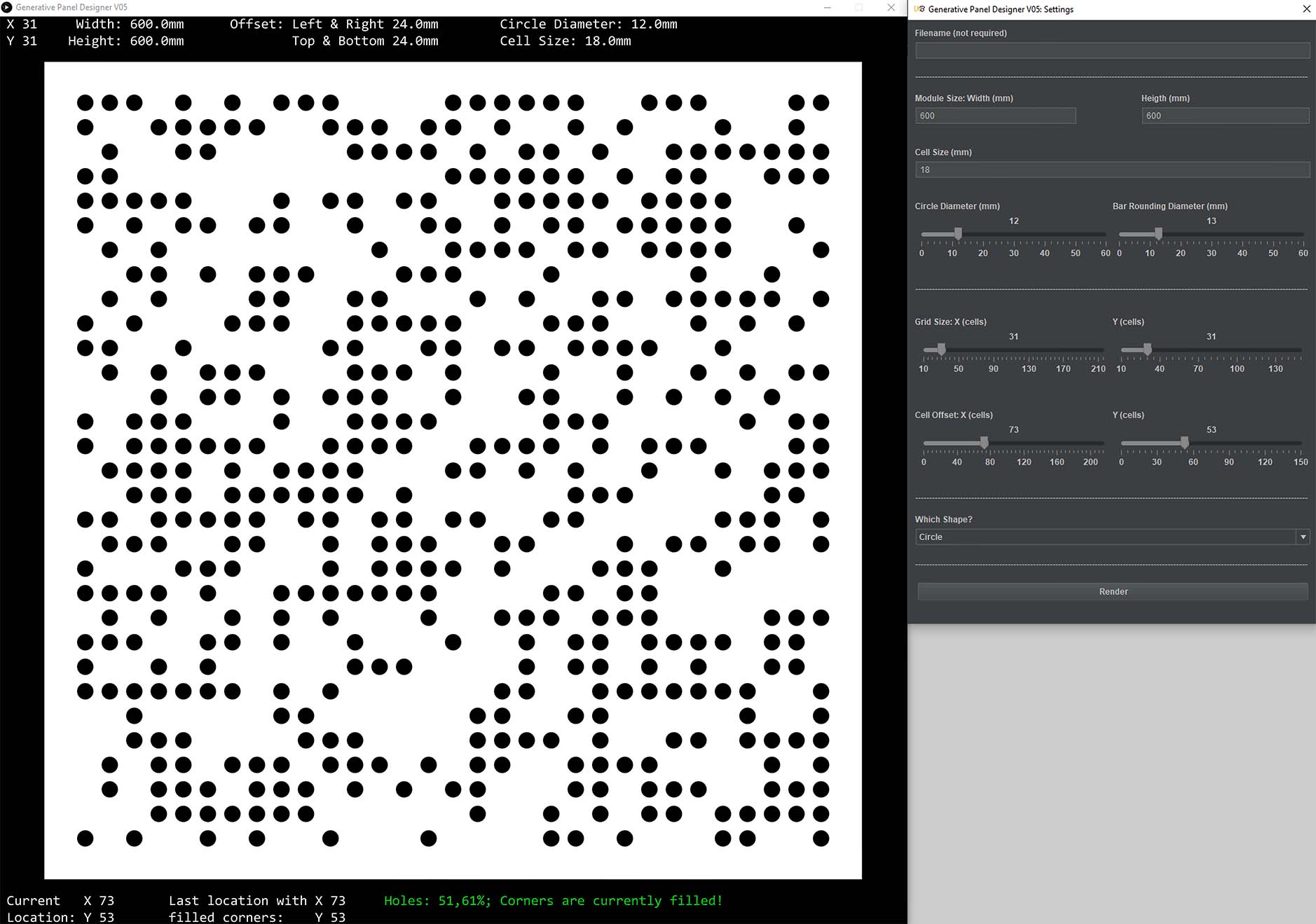

Especially in recording studios, a combination of sound-absorbing and reflecting surfaces are used to model the desired room sound. One special pattern for panels has become established in this context: Defined by a sequence of numbers and milled into the front panel of the modules, it achieves certain desired acoustic properties. The challenge in manufacturing these panels is to generate templates for machine production from raw data, which can be calculated using sophisticated mathematical concepts.

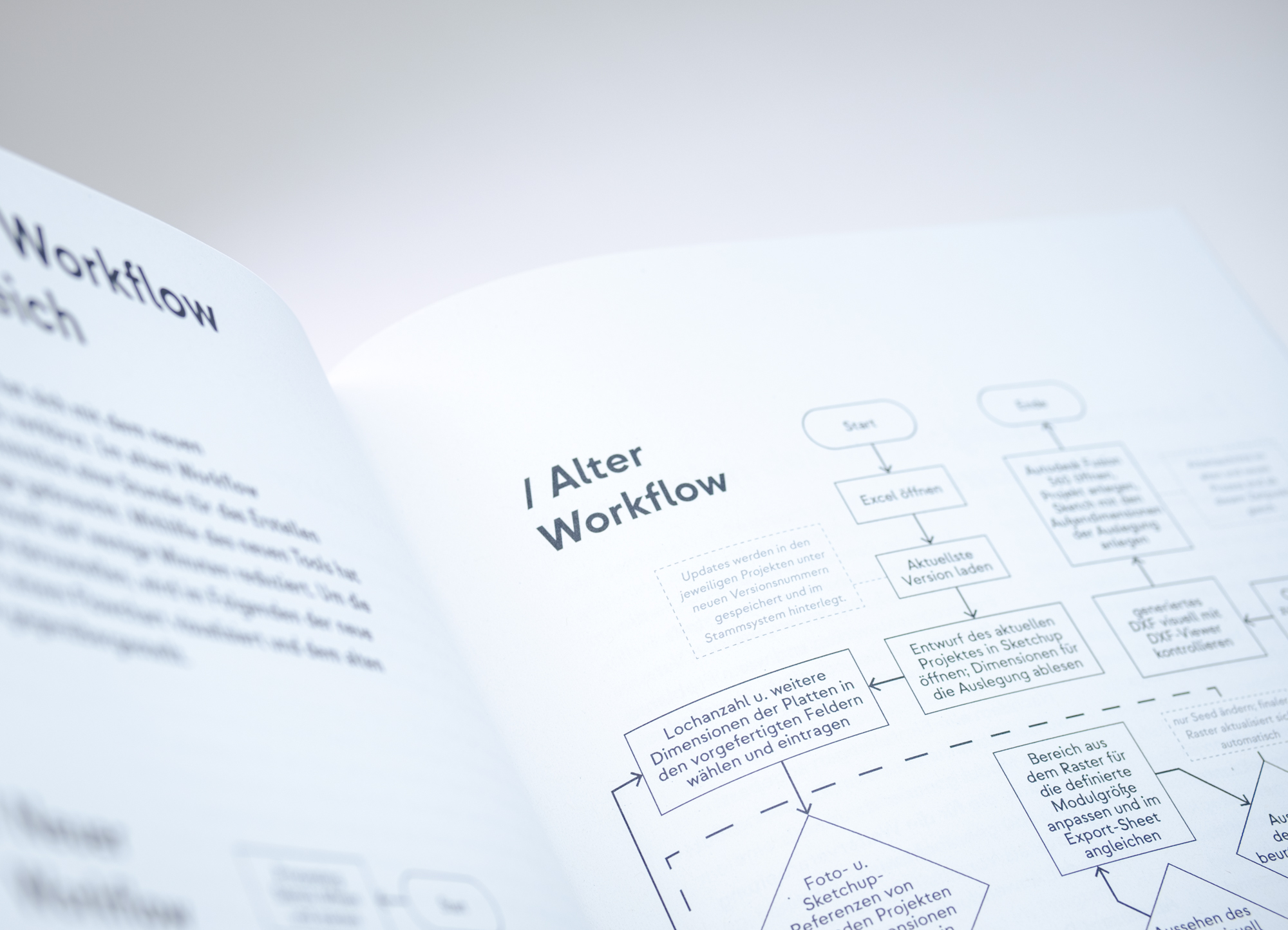

Gernot Ebenlechner has found a way to produce panels with this pattern and installs them in his work as a room acoustician. His son Aaron Nossek deals in this Bachelor’s Thesis with the analysis and optimization of this process and addresses the problems of software development. As a result, a tool was programmed from scratch that makes the panel manufacturing workflow more economical and interactive.