Ready, study, go!

Start your studies top informed.

Study your dream!

All information about studying.

Stay in touch!

Stay connected with the university.

Study with Purpose!

Discover our study programmes.

Advance with Purpose!

Lifelong learning and thinking ahead.

Research with Purpose!

Research from idea to application.

Better together!

As a university we create new opportunities.

Engineering and Production Management

My StudiesEngineering and Production Management is organised as a co-op Master’s degree programme. All students work in a manufacturing company during the two-year programme. Alternately switching between theoretical and practical blocks leads to a continuous exchange of knowledge and experience. As a result projects with practical relevance are the rule, not the exception. Our students spend 15 of the total 24 months in partner firms. In addition to these numerous practical blocks students also work on industrial projects in the theoretical sessions. Very often it is the training employers themselves who approach the degree programme with concrete tasks and so provide innovative projects during the theoretical blocks. Our students also carry out international cooperative projects.

Current student projects

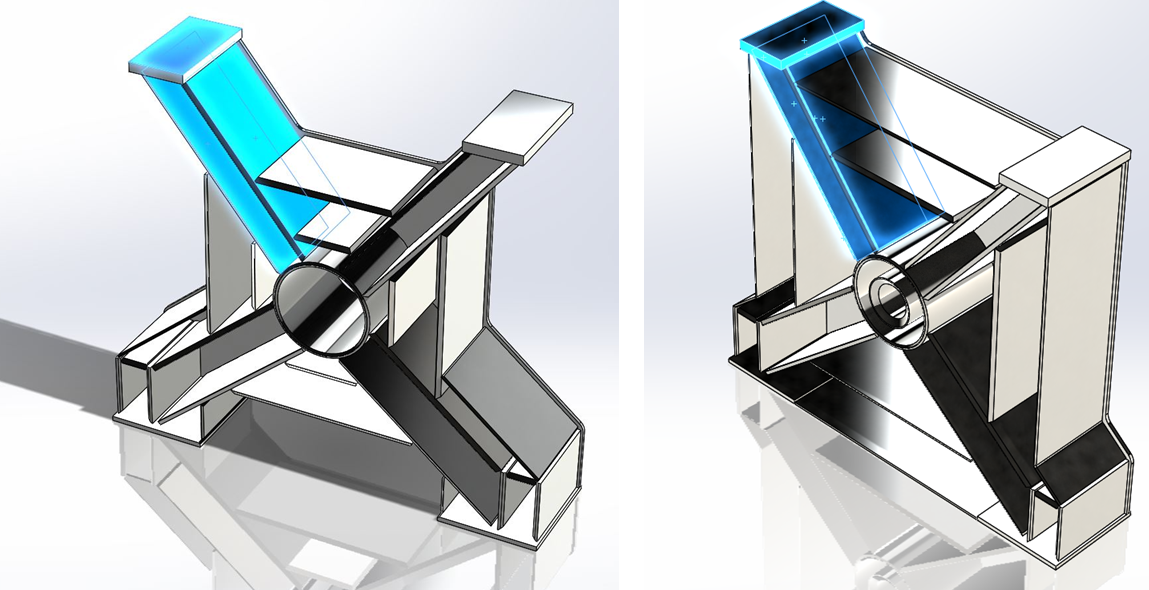

Innovative crusher systems in the mining industry

Photo: © COMEC

This project was carried out with the Italian specialist machinery manufacturer COMEC. (© COMEC)

Jaw crushers are used as primary crushers in mining and also in the pit and quarry industry and serve to pre-crush ores and minerals for the construction industry. This project was carried out with the Italian specialist machinery manufacturer COMEC. Our students developed a new model of a single toggle jaw crusher. This was based on the crusher systems manufactured by the partner firm. The project aimed to analyse machine operation and the production process to reveal potential savings which could be achieved by optimising materials and processes.

- Duration: 2 semesters

- Semester: 1st and 2nd semester

- Project manager/contact: FH-Prof. Dipl.-Ing. Dr. techn. Georg Wagner

- Video

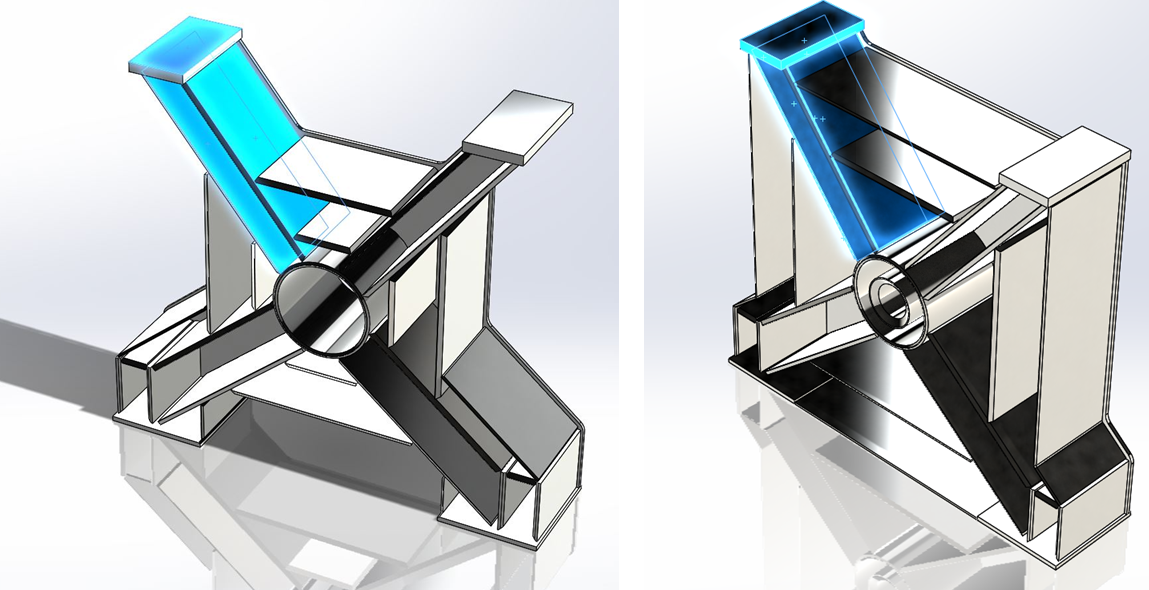

Chamber filter press for fine sand extraction

Photo: © COMEC

In this project the students optimised the construction of a chamber filter press for extracting fine sand. (© COMEC)

Chamber filter presses are discontinuous pressure filters used, for example, for dewatering sewage sludge or clay slurry. The pressure chamber is made up of several successive plates covered with filter cloths and joined together via drill holes. The individual chamber plates are suspended in a frame and pressed together hydraulically. In this project the students optimised the construction of a chamber filter press for extracting fine sand. They were supported by an Italian specialist machinery manufacturer who provided plans and 3D models.

Students first analysed the machine design in terms of the production and assembly stages involved. Based on this analysis, the blank shape and weld process steps were initially optimised from the manufacturing perspective. Geometry and use of materials was then improved using the finite element method.

- Duration: 2 semesters

- Semester: 1st and 2nd semester

- Project manager/contact: FH-Prof. Dipl.-Ing. Dr. techn. Georg Wagner